地址

江苏省无锡市宜兴市经开区 腾飞路29号

Jiangsu ARTIN Automotive Technology Co., Ltd., established in 2017 through the relocation of its predecessor Wenzhou BAVRII Automotive Technology Co., Ltd. (founded in 2006) from Wenzhou, Zhejiang to Jiangsu Yixing Economic and Technological Development Zone, has achieved both production capacity upgrade and smart manufacturing transformation.

With 20 years of specialization in automotive front-end pulley systems since its inception, the company now focuses on engine core components. Its independently developed intelligent tensioner systems and high-precision idler pulley assemblies have made breakthroughs in multiple patented technologies, achieving internationally advanced NVH (Noise, Vibration, and Harshness) performance.

Equipped with fully automated assembly and inspection lines, the IATF 16949-certified enterprise supplies over 10 domestic OEMs. Leveraging the geographic advantages of the Yangtze River Delta automotive industry cluster, the company boasts an annual production capacity exceeding 12 million units, distributing products across global markets.

SATISFYING OUR CUSTOMERS IS OUR CONSTANT AIM

CUSTOMER BASE

CUSTOMER BASE

ONLINE SERVICES

ONLINE SERVICES

AVERAGE MONTHLY CAPACITY

AVERAGE MONTHLY CAPACITY

REGISTERED PATENTS

REGISTERED PATENTS

Please contact us through the hotline or email below

ROTEC's torsional vibration analysis technology is currently the world's first.

The system is used to test and analyze general noise and vibration in moving machinery systems: noise or vibration signals and rotational speed signals are measured by sensors, and through spectral and order analysis, the characteristics of rotating machinery are used to deduce which components are the main sources of vibration and noise, and even the relationship between vibration and rotation angle to deduce the specific location (angle) of component failure, thus providing powerful information for fault diagnosis and optimal design of machinery. This provides powerful information for fault diagnosis and machine design optimization.

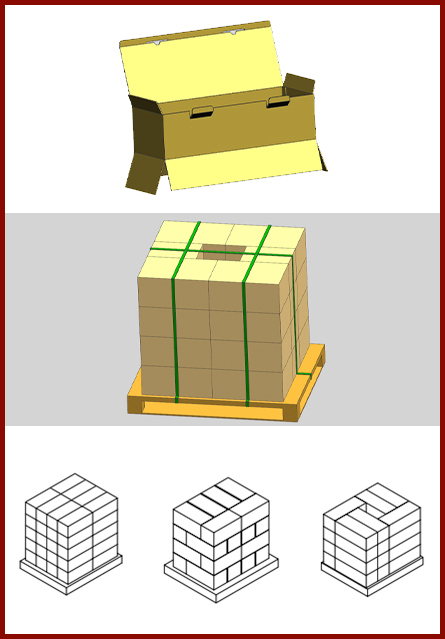

In Artin-Tech(Bavrii),most of the products are wrapped with bubble bags and transparent waterproof bags and then put into a solid and independent box, and finally put into a multi-layer thick corrugated cardboard box and packed into a tray with packing tape and wrap film. The packaging method has passed the drop and moisture test, which can greatly reduce the risk of moisture and bumping of the products.